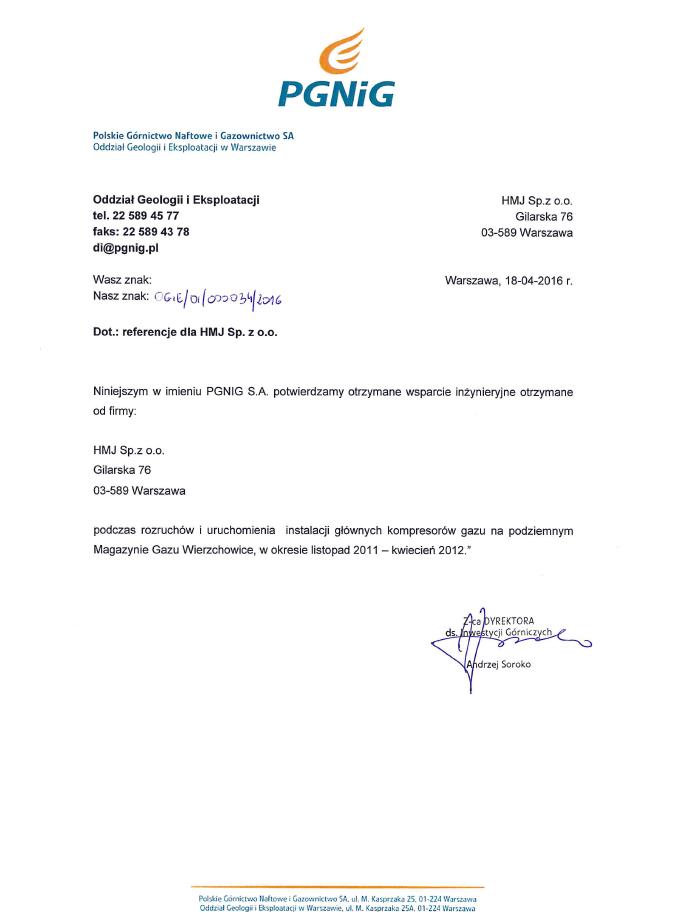

3D Modelling

Professional 3D-modelling software as Bentley Open Plant or Solidworks makes possible

to execute 3D models with arbitrarily high accuracy of the single components, machines, plants and whole factories. Notwithstanding

the big amount of manhours required to produce them, virtual twins of the whole factories, with machinery, material flows, material

data, process data – are the future of the industry. Upon request, we present a detailed offer for such model of the industrial plant of any size.

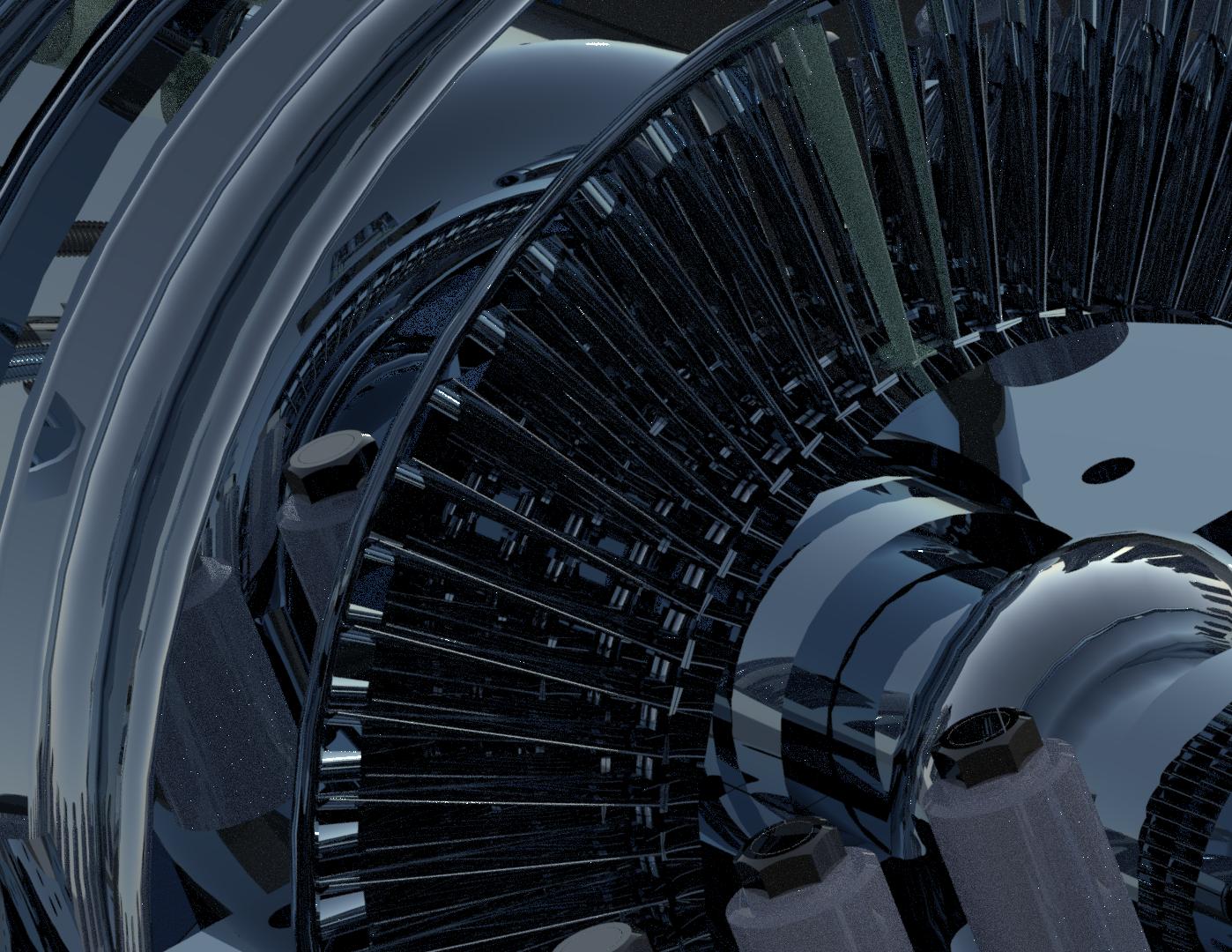

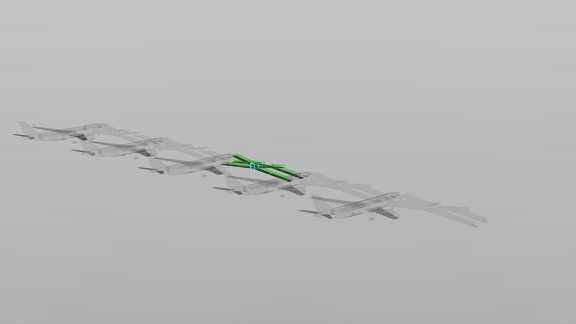

Machinery Modelling

Depending on desired accuracy, we model the casings of the process machines and apparatuses:

compressors, turbines, pumps, motors, reactors, boilers, tanks, etc, with main internals: rotors, bearings, sealings, gears as well as

material flows and animations of the working movements

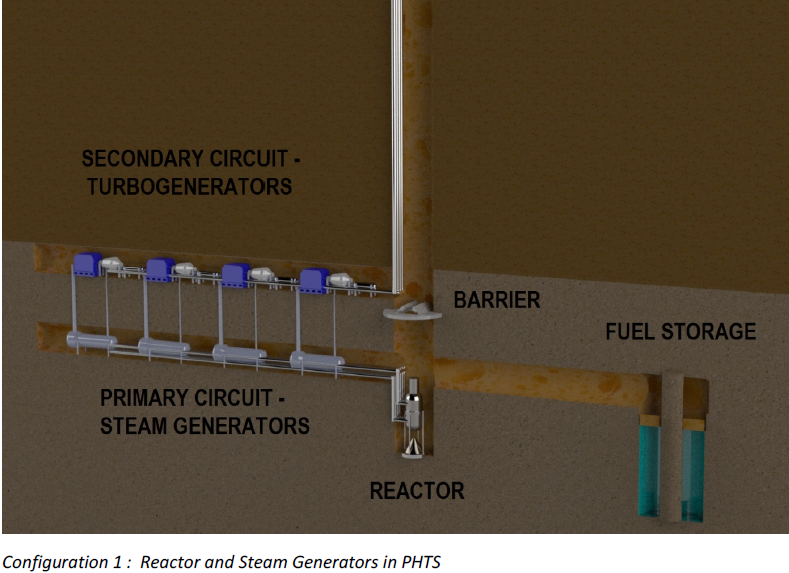

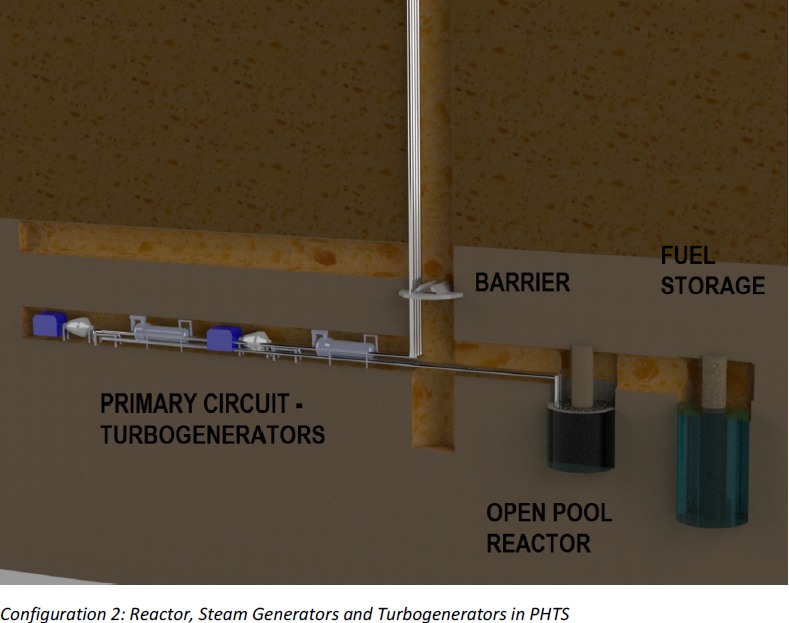

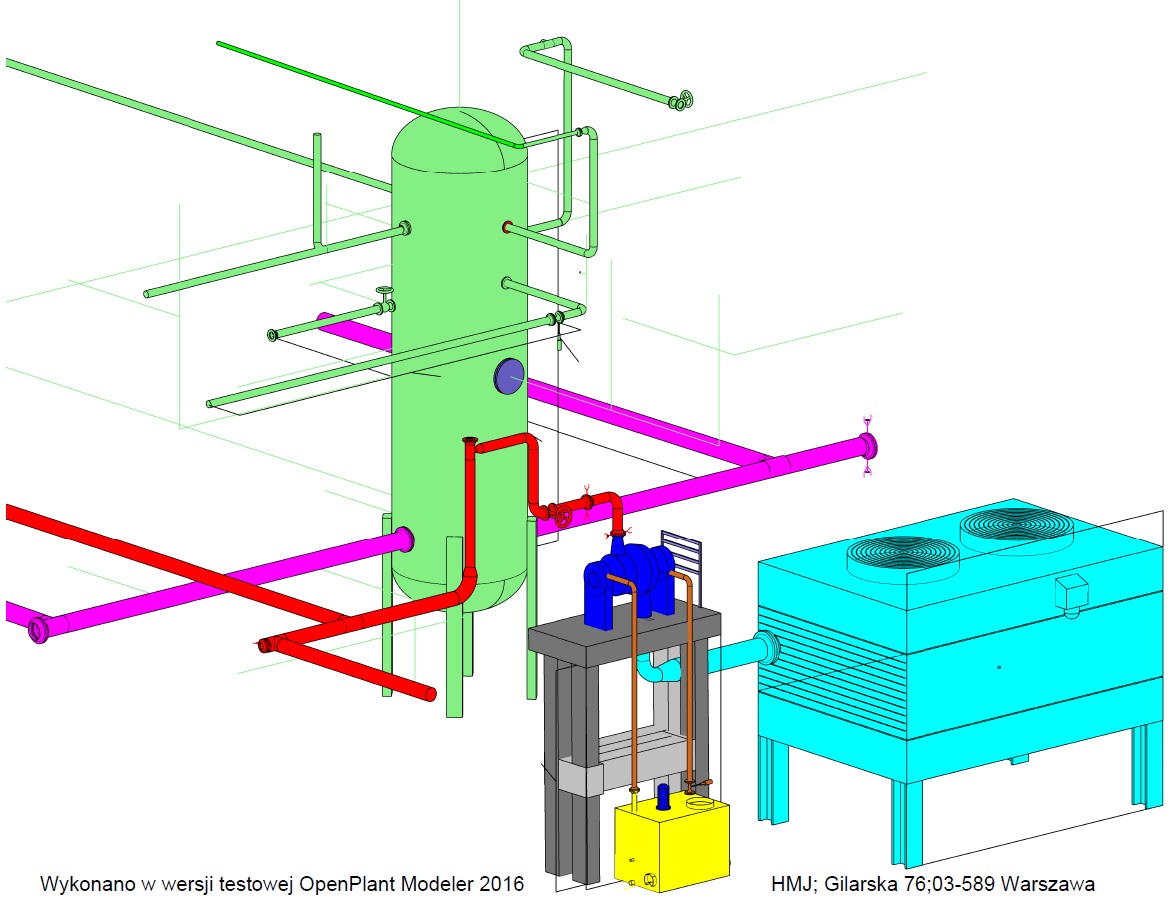

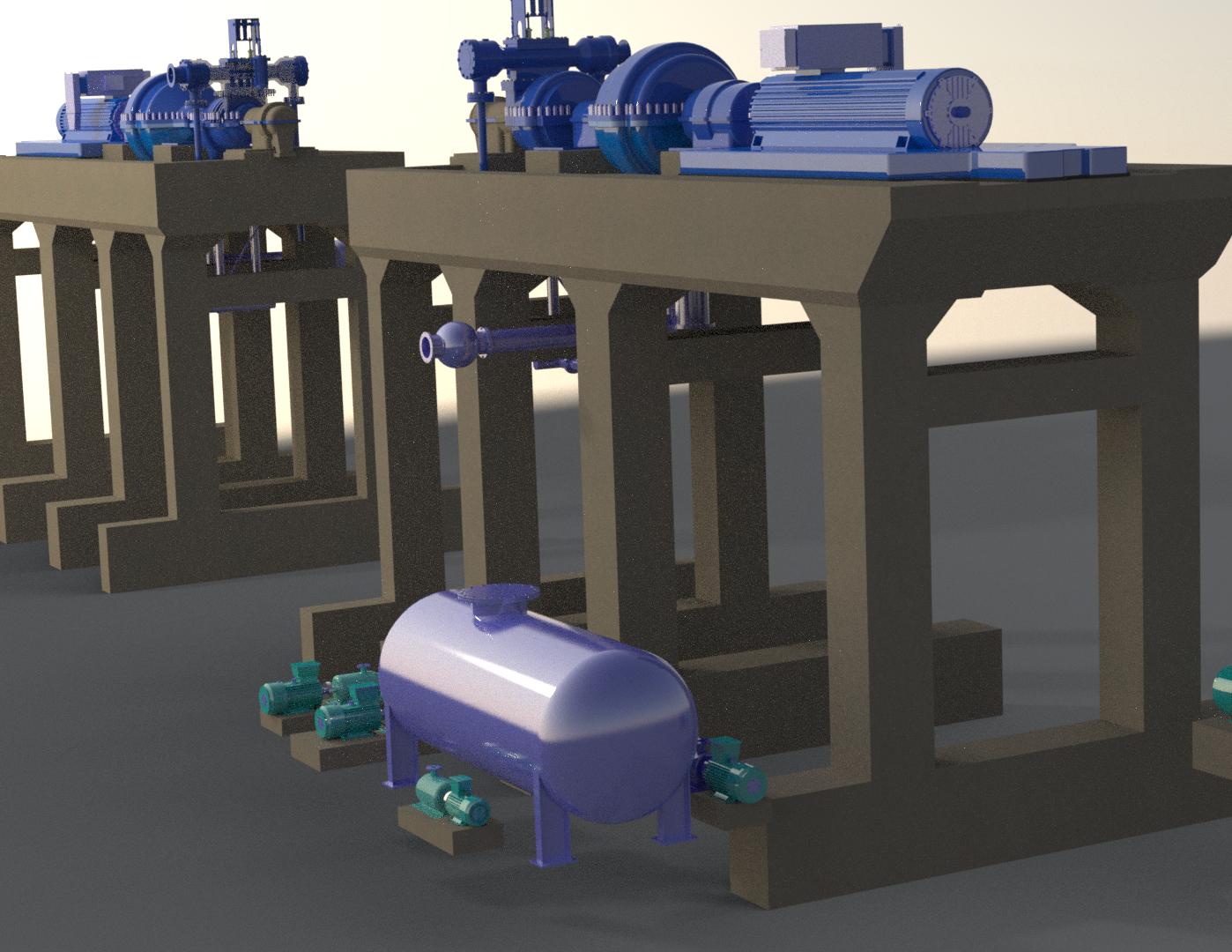

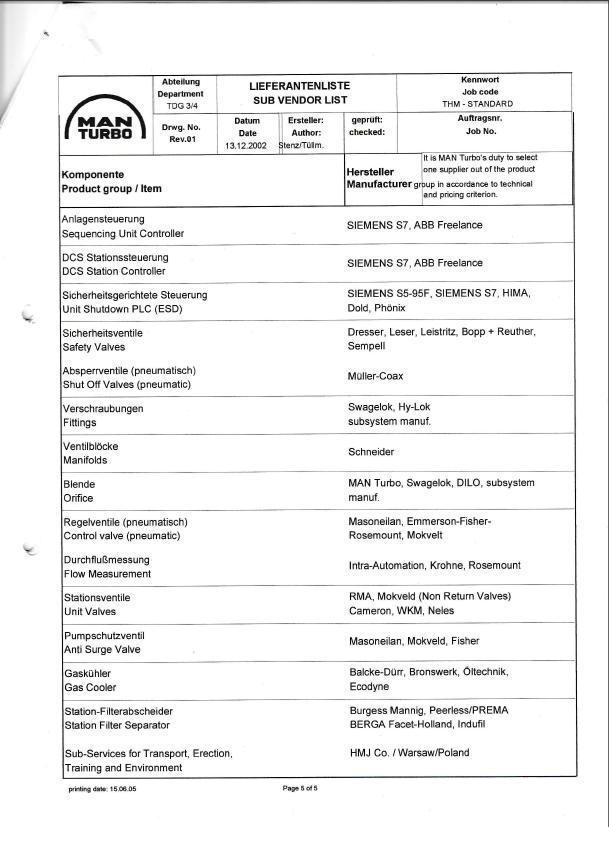

Plant Modelling

We model in 3D the installations with foundations, pipings, machines, apparatuses, valves and

support structures. The modelling can be done to the schematic level with overall dimensions and weights, or – using previously made 3D

models of the individual machines – down to the level of the detail corresponding to the virtual reality.

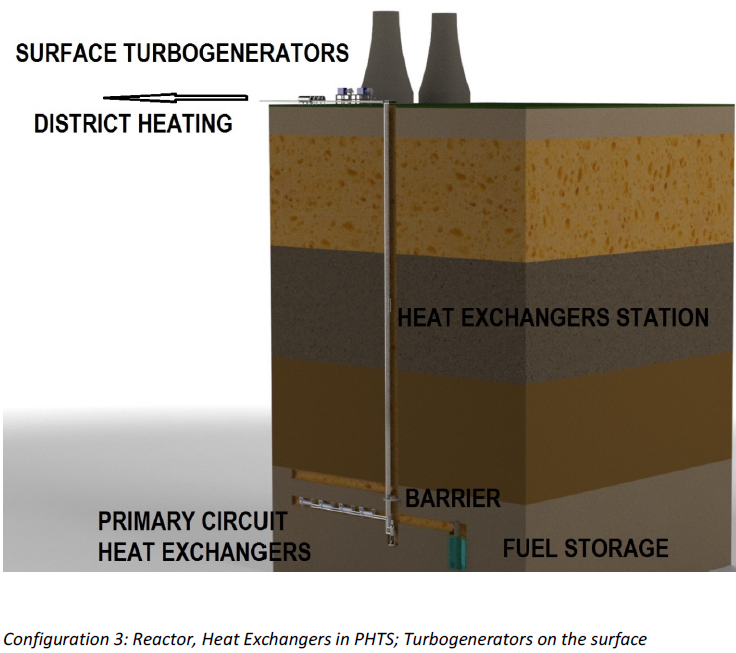

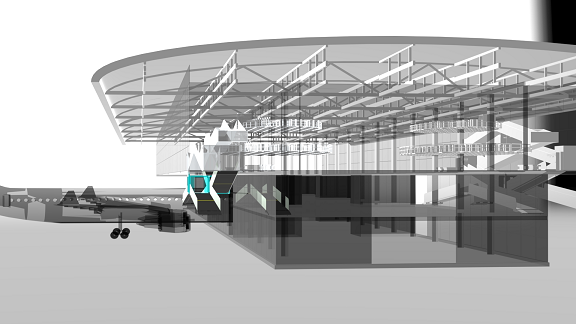

Factory Modelling

Compositing of individual 3D models of the partial installations with internal transport

means as conveyers, roads, walkways, with added terrain shaping, geodetic heights, pipelines and cable lines, buildings and structures

we obtain the model of the whole factory or utility accessible for animations, virtual walk-through, view from many cameras, positioning

on geodetic maps, relative to GPS points and GIS -models.